Everyone thinks about the expensive parts of their engines that are sexy, like pistons, rods, crankshafts, cylinder heads, intakes, etc. But what holds all that stuff where it is supposed to be? Fasteners. Lots and lots of fasteners. And using the right fasteners is something most of us that are serious about making power take seriously. All bolts are not created equal. And either are all nuts. Not by a long shot. But this isn’t about what nuts and bolts you choose, cause we’re going to make the assumption that you have chosen good quality stuff for your project. But unfortunately that is not enough. Not always anyway, because many of you are using the wrong stuff when it comes time to install those fasteners, and we’re going to show you why below.

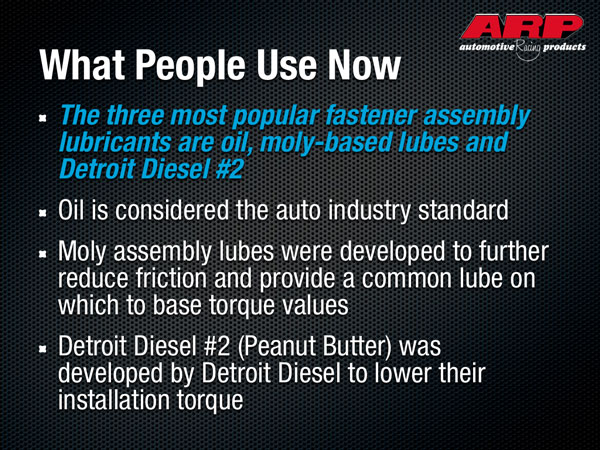

Lets assume in this example that you are the proud owner of a pile of parts that are going to make a stout big block Chevrolet. And that in that pile of parts are all the ARP fasteners you need to hold the important bits in place. If you take said fasteners and dip them in some oil before installing them, or use moly lube, or “Peanut Butter” which is the term given to the lube used by many top fuel teams, then you are doing it wrong. Yes you can get by with some of those, but remember that the professionals are blowing stuff up a lot, or taking it apart way more often than you are, and that means you need it to be right the first time you install it and stay like it should for the long run.

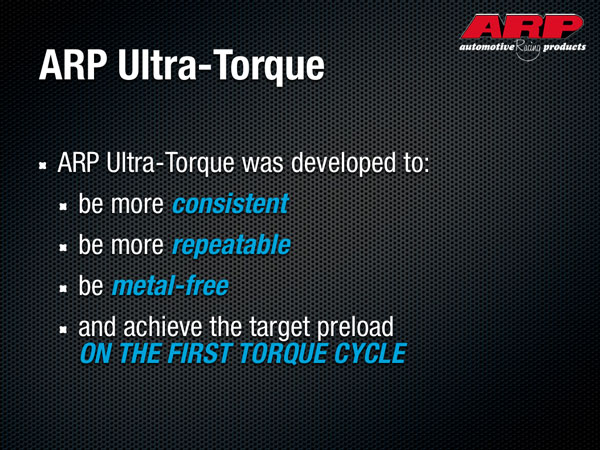

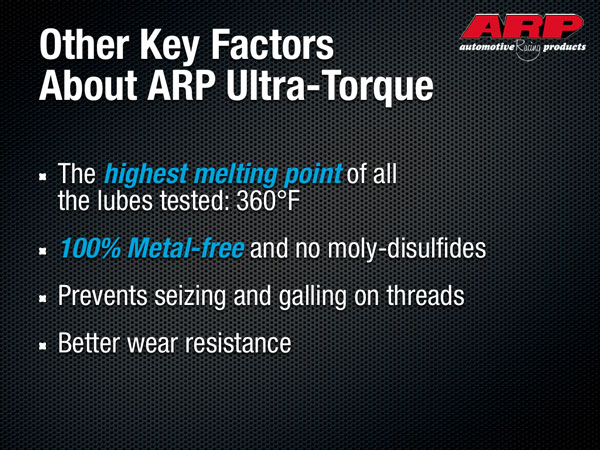

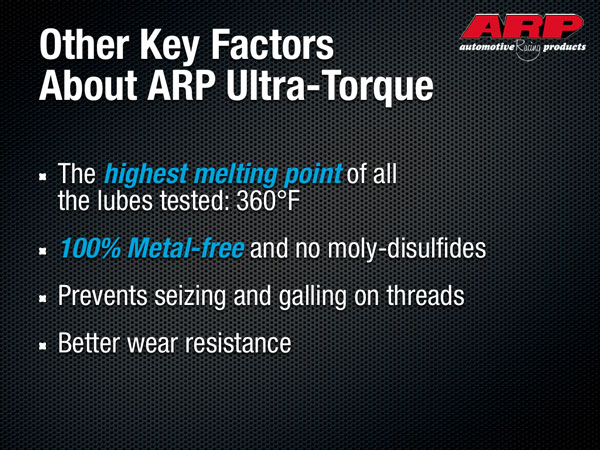

May I introduce to you ARP Ultra-Torque. It’s not new. It’s been around for years. It’s be developed, and refined, and perfected to provide the best torque the first time you install a fastener, and to continue to provide the best torque even if you remove it several times. It’s great stuff. I use it a lot. And you should too.

Here’s why it matters. And it really does matter.

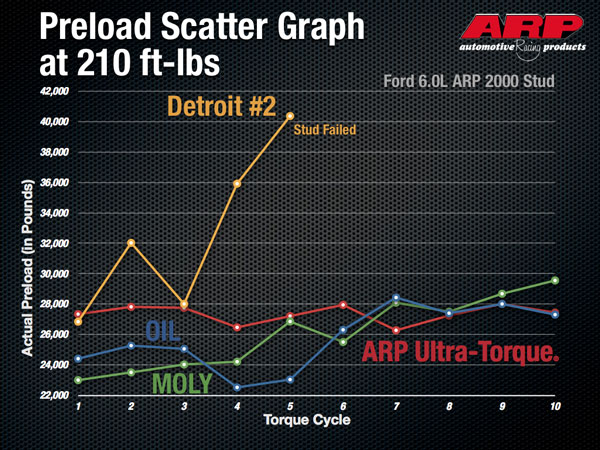

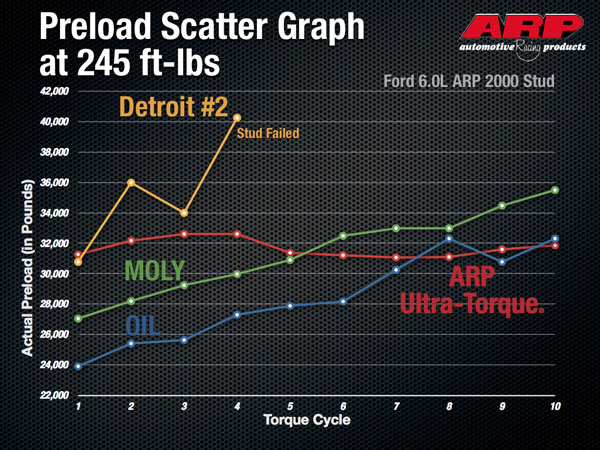

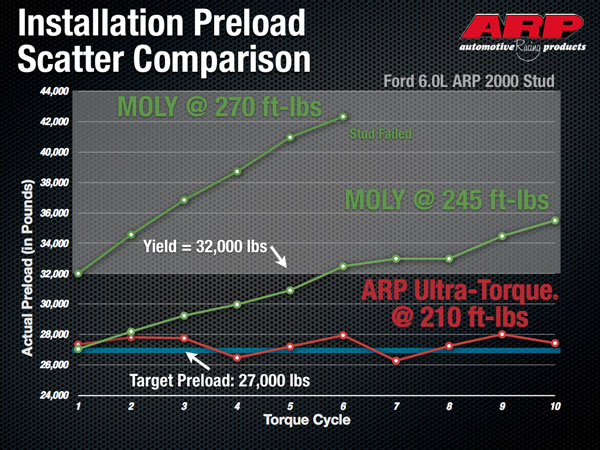

Today’s critical – head studs and bolts, main studs and bolts, and driveline – have been designed stronger than ever before to handle the extreme loads. As a results, installation pre-loads – the amount the fastener is stretched during installation – are very high.

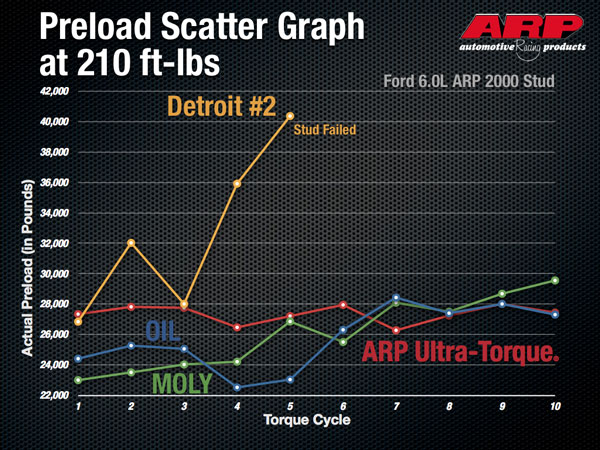

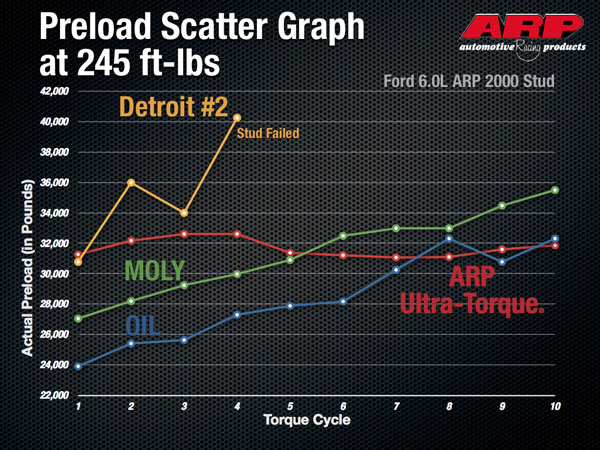

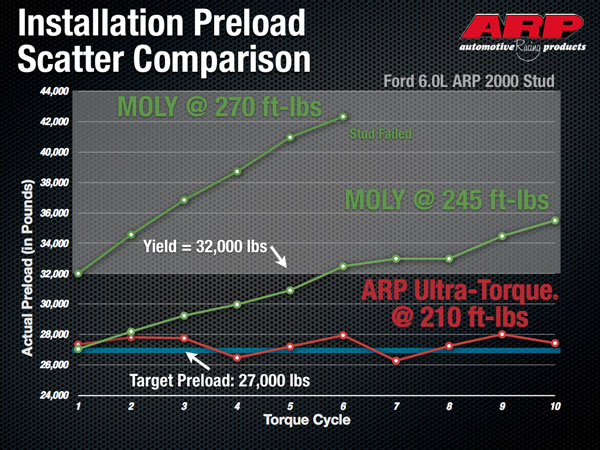

There are a lot of opinions out there about which fastener assembly lube to use and what the torque value should be. First, let’s be clear: ARP provides torque specs for our fasteners based on using ARP Ultra-Torque. If you’re not using our specs and our lube, you have no real idea what pre-load you’re getting. We’ve done the testing where we can measure the torque applied and the resulting pre-loads. We’ve tested with our lube and the others people use…and we’ve got the results to back it up.

For GREAT deals on a new or used Chevrolet, Buick or GMC check out Bosak Chevrolet Buick GMC TODAY!